PPE Decontamination Guide: When to Wash, When to Industrial‑Clean, and When to Retire Gear

Some problems are laundry problems. Others are safety incidents.

This ppe decontamination guide helps you decide when you can do a normal wash, when you need industrial laundering or expert input, and when the safest move is to remove gear from service (and possibly retire it).

Quick Links

- /fr-clothing-care/

- /hi-vis-reflective-care/

- /fabric-softener-on-fr-clothing/

- /diesel-smell-fr-clothing/

Safety note: Always follow the manufacturer care label and your employer’s safety program. If exposure involves hazardous materials, treat it as a workplace safety issue—not a DIY cleaning project.

Quick decision tree (fast)

Step 1: What was the contaminant?

A) Hazardous/caustic chemicals, solvents, mists, fumes, vapors

→ Remove from service immediately. Do not attempt “home fixes.”

B) Flammable liquids (gasoline/diesel/grease/oil)

→ Handle as a fire risk. Wash separately. Avoid heat drying if odor remains.

C) Biological contamination (healthcare/unknown bodily fluids/pathogens)

→ Follow your workplace infection-control policy and manufacturer guidance.

D) Normal dirt/sweat/dust (no hazard flags)

→ Normal laundering per label.

1) Hazardous chemical contamination (remove from service)

If gear is contaminated with hazardous or caustic substances, some NFPA 2112 user guidance states it must be immediately removed from service and retired unless a qualified authority can demonstrate it can be properly decontaminated and safe for reuse.

Also, OSHA’s decontamination guidance highlights that chemical decon can be complex and should be done only when recommended by qualified professionals due to compatibility and hazard risks.

2) Contaminated clothing handling basics (reduce exposure)

- Bag/contain contaminated items (avoid spreading residue).

- Wear appropriate protection when handling (gloves/eye protection if required).

- Keep contaminated loads separate from household laundry.

3) When home laundering is inappropriate

Avoid home laundering when:

- the contaminant is unknown or hazardous

- the garment is saturated with chemical/fuel

- your safety program requires industrial laundering

- you cannot confidently keep the process contained (transport, storage, washer contamination risk)

4) Fuel/grease contamination: dryer safety rule

If clothing is soiled with flammable substances (gasoline, cooking oils, grease, oil), do not put it into a dryer—flammable vapors can ignite. Air-dry outdoors and reassess. If odor persists, stop and escalate (industrial laundering or replacement).

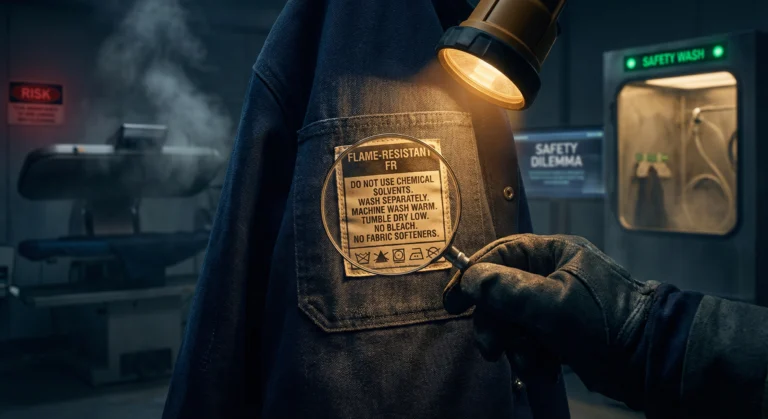

5) FR & hi‑vis special case

FR and hi‑vis gear often has extra restrictions:

- Additives like bleach and softeners may be prohibited by the garment maker.

- Reflective trim can be damaged by harsh chemistry and high heat.

- Contamination can reduce protective performance.

6) “Retire it” signals (common-sense + safety)

Retire or replace when:

- hazardous contamination occurred (unless cleared by qualified authority)

- damage compromises coverage (holes/tears/seam failure)

- reflective trim is peeling/cracked or visibly degraded

- contamination/odor persists after safe laundering attempts

Sources (for references):

10 Comments