When To Replace Hi Vis Clothing: Inspection Checklist For Reflective Safety Gear

When to replace hi vis clothing is not about age—it’s about performance. If the fluorescent background is faded or the reflective tape is peeling/cracked/dull, the garment may no longer protect you properly.

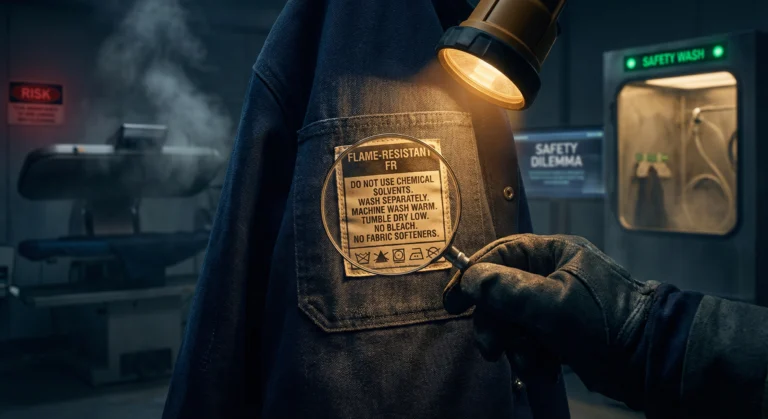

Safety note: Always follow the garment care label and your workplace safety program. Replace hi-vis gear if reflective trim is peeling/cracked or visibility is reduced.

Quick Links:

- /hi-vis-reflective-care/

- /wash-hi-vis-clothing-reflective-tape/

- /wash-hi-vis-oil-grease/

- /ppe-decontamination-retirement-guide

when to replace hi vis clothing: the 7 biggest signs

1) Faded or dulled fluorescent fabric

Daytime visibility depends on fluorescent brightness. If the garment looks “washed out,” replace sooner.

2) Reflective tape is peeling or cracking

Peeling/cracking reduces night visibility. If damage is across working areas, replacement is usually the safest move.

3) Reflective tape looks dull/gray at night

If headlights don’t “pop” the tape like they used to, treat it as performance loss.

4) Tears, holes, fraying, or seam failure

Coverage and garment integrity matter. Damage reduces safety and durability.

5) Permanent grime/oil film that won’t come out

Heavy soils can cover both fluorescent material and reflective trim.

6) Poor fit (too loose or too tight)

High-vis clothing must be suitable for actual conditions. Poor fit can reduce coverage and visibility.

7) Employer/site policy says replace

Some jobsites require replacement at specific inspection intervals.

Simple routine: check, clean, re-check

- Inspect under bright light for fading/damage

- Clean according to the label

- Re-check reflective performance at night (safe environment)

Safety note

UK HSE guidance emphasizes high-visibility clothing should be maintained in a clean state and good working order, and that damaged clothing will not protect properly. That same mindset applies for any Tier‑1 jobsite: condition matters.

One Comment